39 racking systems warehouse rack labeling ideas

New Warehouse Design? Tips on How to Label Warehouse Racking - LIDD When creating a numbering system, there are always lots of opinions on how to label warehouse racking optimally. At LIDD, we know that ultimately there is not one perfect numbering system for all our clients. With any method, the key factor is to stay consistent and flexible. To do that, we typically recommend a matrix style numbering system ... Warehouse Racking: The Ultimate Guide - Conger Industries Inc. Double-reach - also called double deep - racking systems are very similar to selective racking. But instead of using one row, racking is placed two rows deep. Double deep pallet racking allows double the storage of single selective racks Racking could even be placed both back-to-back and two rows deep on each side, therefore maximizing density.

Quick Tips for Warehouse Rack Labeling Systems 4) Pair Rack Labels with Floor and Aisle Signs Floor and aisle signs displaying numbers or rack ranges make it easier to see which zones or sections are within a warehouse aisle. Because they're easy to see from a distance, floor tape and signs are ideal visual cues to help employees find the right rack.

Racking systems warehouse rack labeling ideas

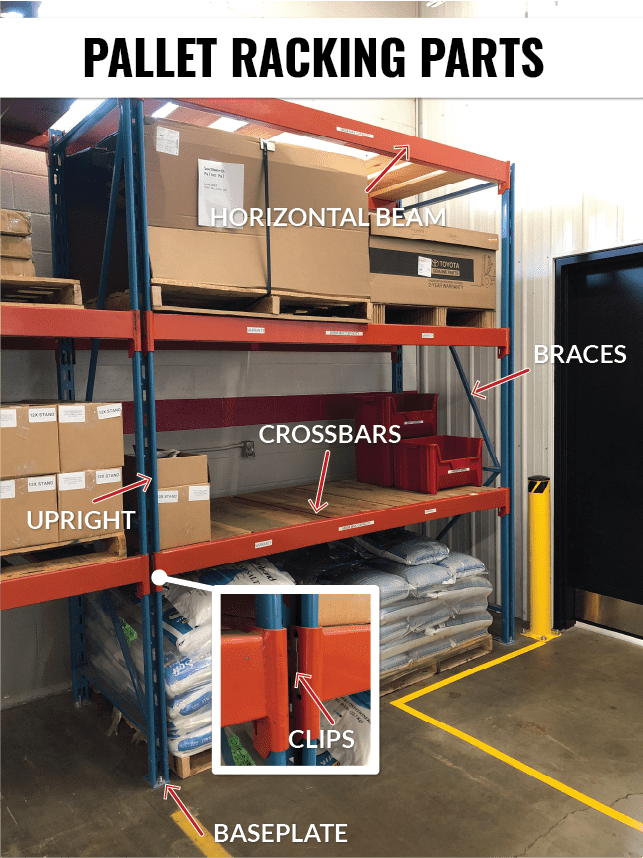

Warehouse Signs for Aisles, Racks, Docks & Hanging Locations Warehouse Signs. Card & Label Holders. Warehouse Magnets. Labels & Cards. Other Supplies. All Products. If you have any questions or concerns, please contact us at sales@shelftagsupply.com or call in at 800-851-8980. We are open Monday-Friday 8am-5pm EST, USA. Rack Labeling Resources | Creative Safety Supply Rack labeling is an incredibly useful warehouse organizational tool and it only requires three components. Labels - these can be standard peel and stick labels, magnetic, cold-storage, reflective, and even totem-rack labels. There are countless types of label material to choose from that fit the needs of any facility. Warehouse Racking Safety Guidelines: Satisfying OSHA A plastic pallet that is loaded to its maximum capacity could be shipped from a warehouse equipped with racks that will hold the weight to one that has a less capable racking system. Printing the load weight on a pallet license plate is one solution, but these labels are easily lost in transit.

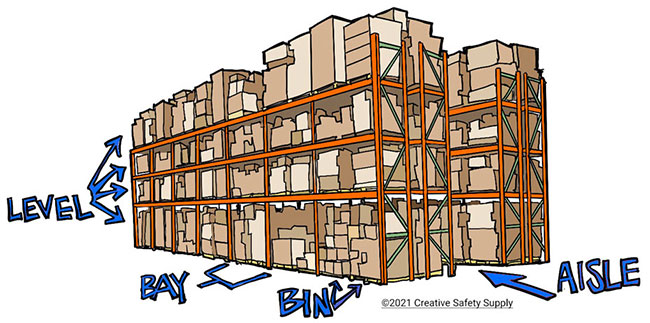

Racking systems warehouse rack labeling ideas. Warehouse Racking Systems | Material Handling Equipment - Used Pallet Rack Reorder Labels; Sold Out; Application for employment; Locations. Houston - Headquarters & Sales; ... Let us help you determine the best rack layout for your warehouse. Not only do we sell racks & shelving, but we also offer delivery, installation, dismantling, complete facility relocation, powder coat painting and much more. ... Used Pallet ... Top Warehouse Rack Labeling Ideas to Boost Efficiency After organizing the contents of your racks and shelves, start labeling them from the bottom up. This method makes it more convenient to increase the number of layers of shelves as your warehouse scales up. The lowest row should be named "01". The second row from the bottom is "02" and so on. How to Label a Warehouse Rack - Camcode Jul 22, 2022 · At Camcode, we provide rack labels for all applications, environments, and price points. For a more durable alternative to paper-based labels, Polyester Warehouse Rack Labels are a great choice. These specialized labels serve as highly-durable, permanent labeling solutions that adhere to a variety of surfaces – including uneven or bumpy surfaces. Warehouse Racking Tips and Tactics: 50 Expert Warehouse Racking Ideas ... - Chance Cook, Warehouse Set Up: 11 Tips That Will Help You Lay Out Your Warehouse, Jorgensen Material Handling 2. Budget your project. "The first thing to consider is the projected cost of your new racking - as well as the cost of designing and installing your solution. "It's not always about going for the cheapest.

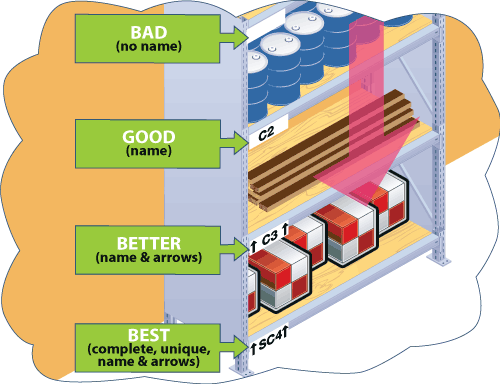

Common Types of Warehouse Rack Labels - Informs Inc. Here are the most common types of warehouse rack labels: Warehouse Rack Beam Labels These are the labels you will most commonly find on warehouse racks. They mark each bay location, and typically use 2D barcodes for scanning. They may also have letters and numbers for workers to identify contents without scanning. Warehouse Labeling | Labeling Solutions for Warehouses - Express Corp Consistent numbering, color, size, and format of your labeling will go a long way to keep your system organized. Rack Labeling. The two most common ways to label racks are serpentine and standard. A serpentine labeling system allows a picker to weave (like a snake) up and down warehouse aisles and collect products. Warehouse Racks Labeling Guide & Idea - SPS Ideal Solutions Label from Bottom to Up: It is always a good practice to stick the warehouse racks label from bottom to up. The bottom row must carry the serial no 01, and when moving upwards it must be 02, 03, and 04 and so on. This practice of numbering is beneficial when there are any future upgrades by adding rows to increase the height of the racks. Warehouse Racking and Storage Solutions - Crown Equipment Corporation Improve the Efficiency of Your Racking and Storage Making the most of your warehouse space is a common challenge and choosing the right rack system is critical. Crown can help determine the right combination of warehouse racking solutions to fit your space and your storage requirements. Schedule a Consultation or Call 1-844-215-6560

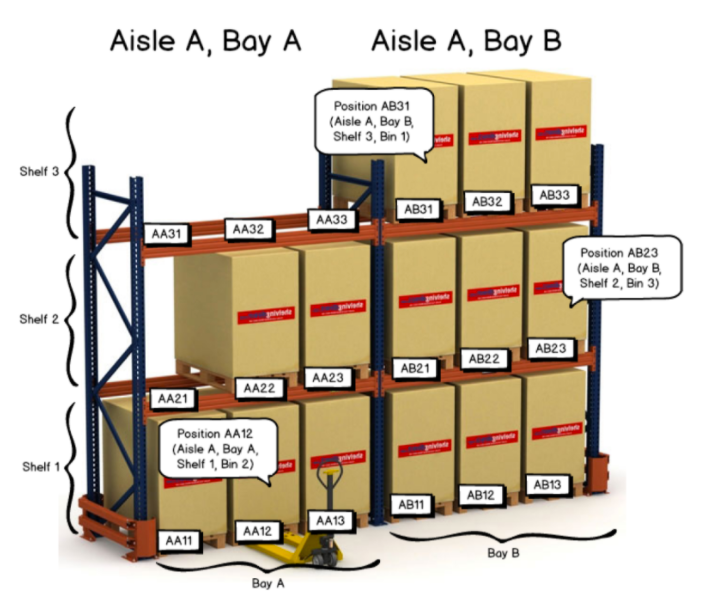

8 Warehouse Organization Ideas You Can Implement Now - EMERGE App 2. Install Warehouse Racks and Shelves. So, you just moved into a new home. It's time to bulk out the storage areas a bit as, well, you have a lot of things to keep and you can't bear to throw them all away. Heavy-duty shelves are planned for the garage because that's where tools, paint and solvents belong. PDF A Guide to Warehouse Racking and Storage Types - Cen Global® Double Deep pallet racking is another simple way of placing one pallet behind another. Using a double deep lift truck, the operator places the back pallet into the rack first, then places another pallet in front of it. However individual access to the pallet is compromised. Drive -In Figure 2 Creating a warehouse location numbering scheme? Read this first! If you have more than 9 levels you should start with 01. Position - assign numbers to each position ascending from 1 to 9, from left to right as you face the rack. Here's an example of a location label where the format is Aisle - Rack - Level - Position. In this case, Aisle 01, Rack 02, Level 1, Position 1. Keep it short and sweet. Rack Labeling | Creative Safety Supply In many warehouses, a racking solution will involve high density and multiple levels. Even smaller operations often have something like two-shelf pallets. If you have more than one level of racks, it's recommended to label from the ground up and start by giving the row closest to the ground a label such as "01".

Guide to Warehouse Rack Labeling System - BHD Vietnam Racking Factory Involve them right from the planning stage. Invite them to your facility or send them clear images of your facility and explain them the layout and structure of racks. Allow them to walk through the warehouse and see the rack arrangement. This helps the manufacturer to have a clear idea of the warehouse racks labels' application area.

Racking Systems Warehouse Rack Labeling Ideas - Multiplicites Racking systems warehouse rack labeling ideas. You are limited in the depth of storage for a particular bay by the size of your facility. Position assign numbers to each position ascending from 1 to 9 from left to right as you face the rack. Reach Truck Drive-In Racks allow a lift truck to enter the rack from one side to pick up or pull out pallets.

Rack Labels - Imprint Enterprises Warehouse Rack Labels Rack labels and shelf labels are a necessity to streamline the workflow of your warehouse. With clearly labeled racks and shelves, your staff will be able to quickly locate and identify the right inventory for stocking and shipping. Visually attractive, multicolored graphics allow for easy tier identification.

Best Warehouse Labels and Labeling Ideas - BlueCart Since racks are the least likely type of shelving to be moved, applying warehouse rack labels should be done as soon as possible. There are two common approaches for warehouse rack labeling ideas: standard labeling and serpentine labeling. In standard rack labeling, products are labeled in parallel structure.

Warehouse Racking and Pallet Rack Systems: Different Types and Design When designing a pallet rack system, some of the factors you need to understand are: total # of SKUs, total # of pallets, weight of material, inventory retrieval method, turnover time, and whether these will be full or split case picks.. Warehouse pallet racking can vary so much in terms of specifications, applications, and configurations. No two racking systems are exactly alike, and one ...

2 Labeling Solutions for Warehouse Inventory Location Flexibility Clean Release™ Repositionable Label For new racking systems, consider starting with a preprinted, repositionable barcode label. A removable/repositionable label makes it easy to relabel rack locations in the future. They are simple to install and offer inventory location flexibility, without any need for scraping or cleaning to remove them.

Warehouse Locations and Bin Labeling: Best Practices and Tips - SkuVault The industry preferred method of shelf labeling is by section (see graphic). Depending on the warehouse and their needs, you might choose to put the shelf value in the last position of your location code. This would mean your shelves are organized "vertically" or "by shelf".

4 Proven Options for Relabeling Warehouse Racks - ID Label Inc. Magnetic warehouse rack labels are popular because they are easy to place and move, and they offer a good long-term return on investment. 3. Removable Warehouse Labels If your beams are in good shape, consider using a preprinted, removable barcode label. Like the other options above, a removable label makes it easy to relabel rack locations.

How to Label a Warehouse - Express Corp Warehouse labeling systems ensure a great load of benefits, such as, decreased manual entry errors, efficient accessibility, increased turnover, optimal safety. ... Multi-level racks: Warehouse rack labels are used to streamline workflow by making items and sections easier to identify for employees. They help identify the right products for ...

Warehouse Racking Safety Guidelines: Satisfying OSHA A plastic pallet that is loaded to its maximum capacity could be shipped from a warehouse equipped with racks that will hold the weight to one that has a less capable racking system. Printing the load weight on a pallet license plate is one solution, but these labels are easily lost in transit.

Rack Labeling Resources | Creative Safety Supply Rack labeling is an incredibly useful warehouse organizational tool and it only requires three components. Labels - these can be standard peel and stick labels, magnetic, cold-storage, reflective, and even totem-rack labels. There are countless types of label material to choose from that fit the needs of any facility.

Warehouse Signs for Aisles, Racks, Docks & Hanging Locations Warehouse Signs. Card & Label Holders. Warehouse Magnets. Labels & Cards. Other Supplies. All Products. If you have any questions or concerns, please contact us at sales@shelftagsupply.com or call in at 800-851-8980. We are open Monday-Friday 8am-5pm EST, USA.

Post a Comment for "39 racking systems warehouse rack labeling ideas"